Sidd’s diary charting the jobs and processes which will ultimately see him returning to the road.

May 2025

Wheel PCD Adaptors and Distributor

This month has been the continuation of making the wheel adaptors and also we have finally got around to completing the distributor conversion and we now have a means of driving a rev counter

February 2025

Wheel PCD Adaptors

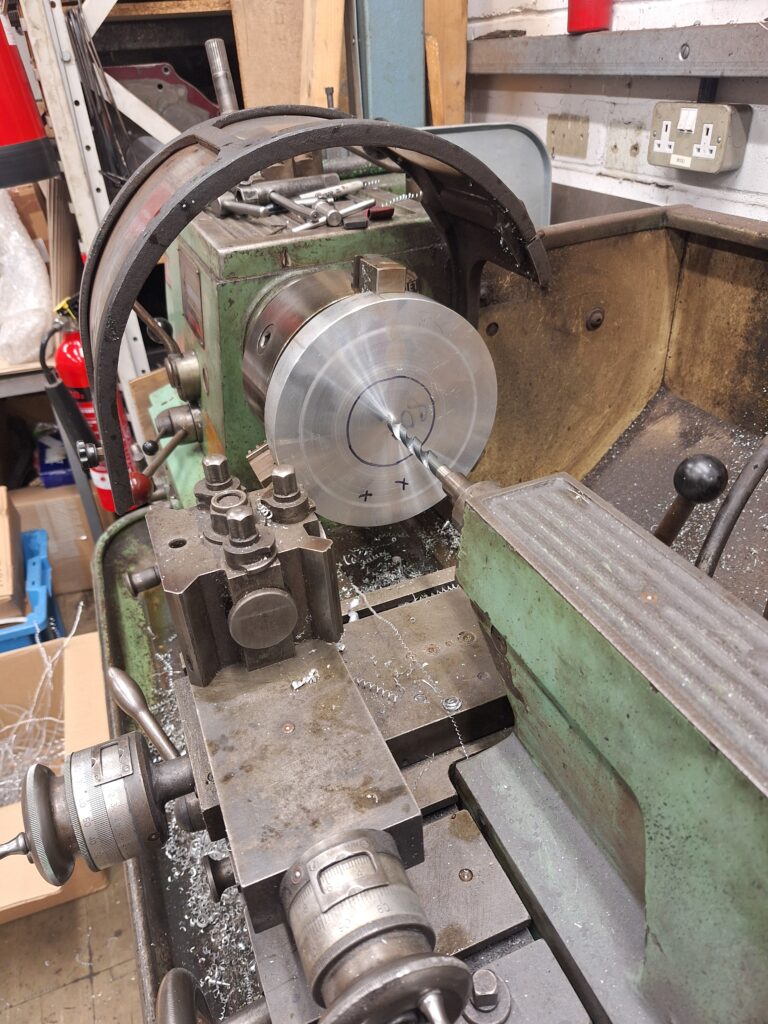

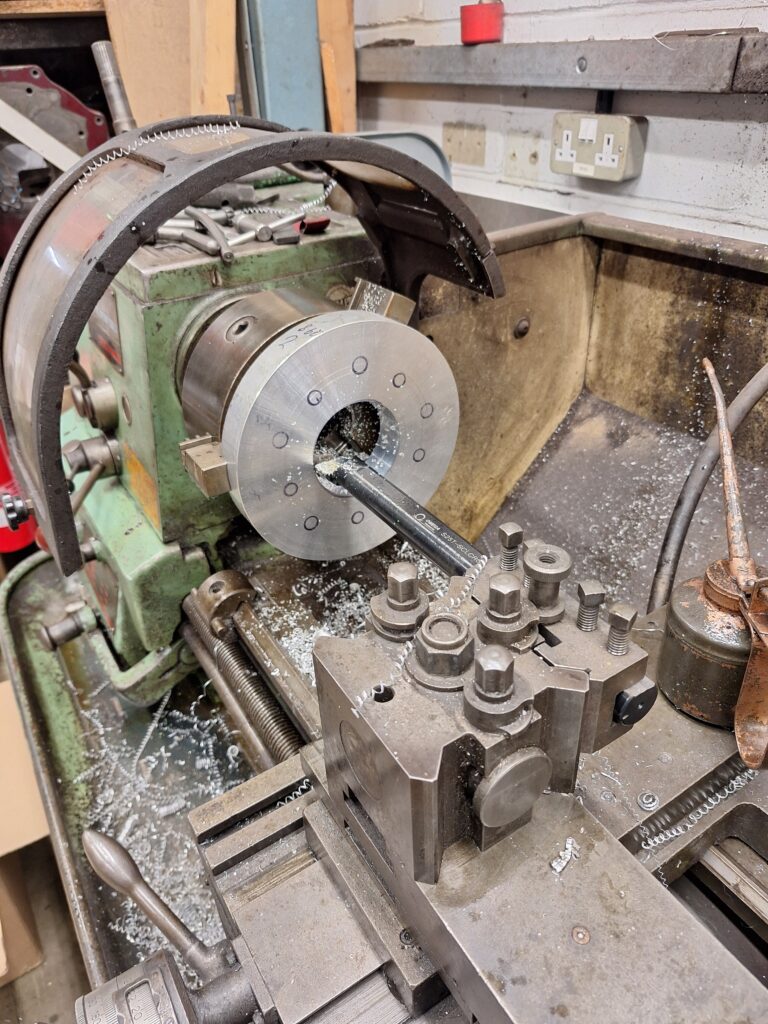

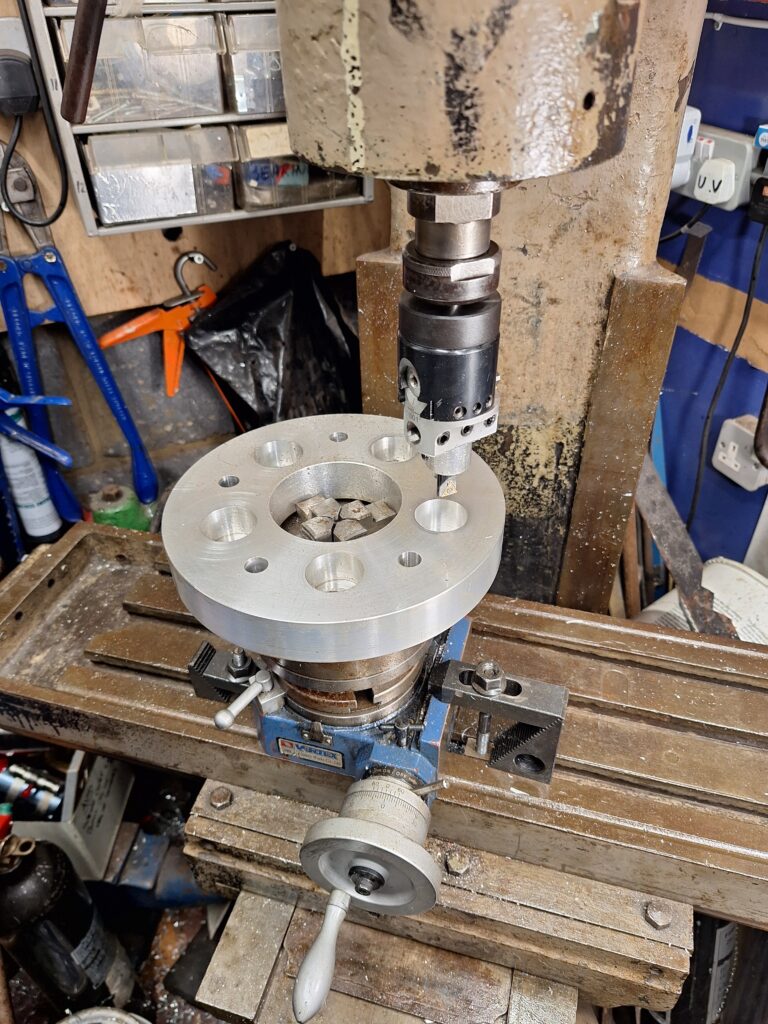

This month has been spent making adaptor plates to allow the fitment of the Ford wheels, Alloy blanks where ordered then trued up on the big lathe, the centre was bored to 82mm and then transferred to the mill.

5 recesses were bored to accept the Armstrong wheel nut then 5 more holes were bored and spaced between them at a larger diameter to accept 1/2″ unf wheel studs.

Also picked up another gasket set from Ebay, always good to have spares.

January 2025

Engine Reassembly

Engine re-build started properly with the start of 2025, crank and new main bearings fitted and torqued down. Camshaft installed and the timing gears and chain fitted and timed up. Pistons fitted to the con rods and all 6 sets of rings gaped. Unfortunately when we went to fit the new big end shells the box had been miss labelled and completely wrong shells had been supplied. Hopefully this is a simple mix up by the suppliers and fingers crossed is easily resolved. Moving away from the engine shop we moved into the barn for a few hours to install the servo on its new bracket made last month and more brake lines were made.

Also tackled on this visit to the barn was the subject of wheels, while scratching around doing something unrelated early Ford wheels came to mind. Model A wheels are the right diameter 21″ and 5 stud but with a different stud diameter to Armstrong Siddeley , the thought is with an adaptor plate they could be made to fit. The hunt is on for Model A wheels and with luck we may have some before the month is finished.

We had a stroke of luck and found a set of 5 wheels and tyres on marketplace, day out to Sussex to collect them. Next job is to make a set of adaptor plates.

December 2024

Engine has returned

December and the engine was finally collected from the machine shop. 0.30″ oversized pistons, 0.20″ grind on main bearings, 0.10″ grind on big ends, the components have been put in the engine shop and hopefully will start being re-built in January.

Another addition to Bay 7 is a bench from the workshop of the Royal Engineers Museum Chatham and a vice found in the back of Alex’s welding shop. First job was the fabrication of a bracket for the new after market brake servo. The diff cover was re-fitted with new gasket, level plug and oil.

November 2024

Barn visit and surprises

Barn visit November started with a very nice surprise from Alex, a pair of 8″ Lucas head lights and matching side lights followed by a large handbrake arm ( probably off a truck but it’s in keeping with our style ) donated to Sidd. Rear leaf springs and associated bushes and linkages re-fitted. Hand brake pivot and a few other brackets re-fitted as well. Tried to remove level plug on the diff to re-fill with oil only option after various spanners and blow torch failed was to remove cover plate to the workshop where the level plug lost the fight. As the differential is a Salisbury type a new gasket and plug are quite common as they are used on many vehicles from Land Rovers to E-Types so are easy to source.

August / September 2024

More cleaning and painting

While we are away from the barn there are a few small jobs we can get on with. Cleaning and painting all the rear leaf springs and all their associated brackets, bolts etc. Fan belts have been purchased, they are the same as used on Land Rover Series 2A. Plasma cutter has been employed to make support brackets for the front engine mount bracket, these have been made longer and will be cut and welded when the engine is reunited with the chassis. Poly bushes have been sourced for the leaf spring shackles, they are a Ford kit which are a little long so 5mm was removed with the help of the mill.

July 2024

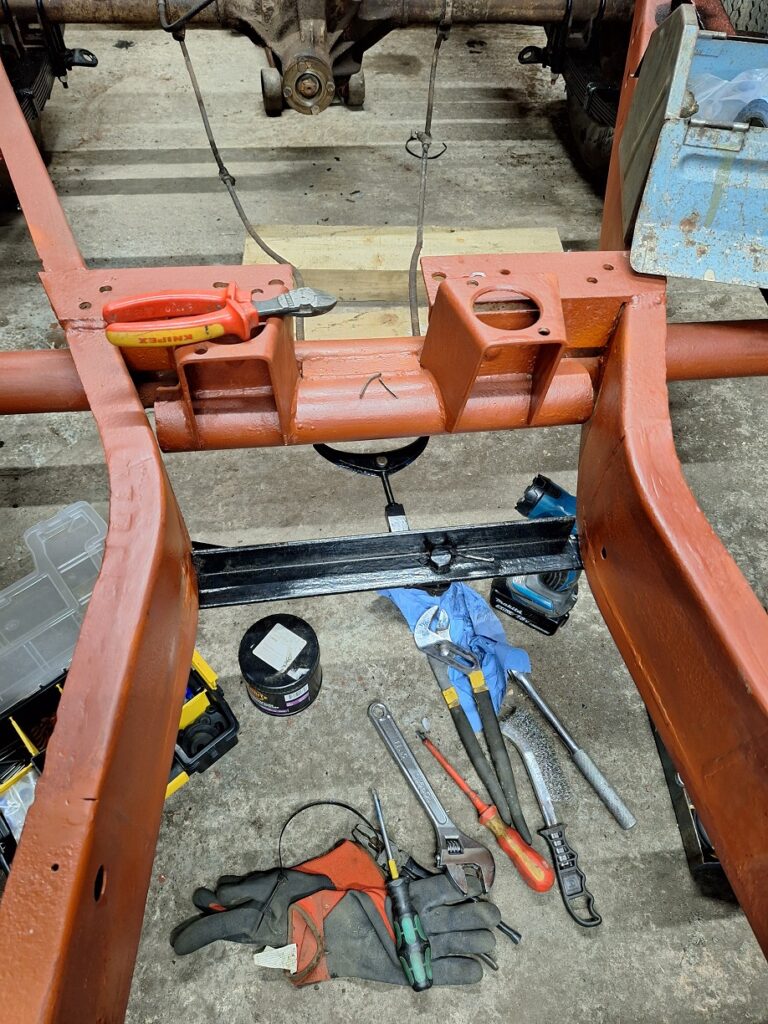

New Home and Chassis Welding

July saw Sidd moving into his new home in bay 7 in the M.T. shed. Lights and power have been installed and he has a dry corner to call his own and allow the journey to continue. The hole that was found under the chassis has been welded and a few other welds tidied up and with the chassis exposed cleaning underneath and red oxide could be done. Final job of the weekend was to drop the rear axle and remove the rear springs for cleaning and inspection back at home.

June 2024

More Jobs

Purchased another distributor from a TR6 which has a tacho drive so hopefully will be able to drive the rev counter purchased last month by installing my original distributor internals into it.

May 2024

Jobs

The weather has finally cleared enough to allow more works to continue on the barn roof.

Bit of time spent on Sidd this month, chassis cleaning, removing of engine mounts, stripping of bulkhead and a bit of playing mocking up the look.

We were donated a front grill off a 1930’s Sunbeam Talbot 4/3Litre and an aero screen ( another will be purchased to match)

Also a friend was moving and a nice 1.75 ton trolley jack was donated to Sidd, thanks Paul.

Just won on Ebay a dash board, mainly want it for the speedo and rev counter.

March 2024

Bodywork

As Sidd has no bodywork you have to start somewhere, the body on a late 20’s early 30’s Humber 16/50 tourer which was bought to be used as a donner vehicle was available. It has some usable panels and it’s easier to actually start with something and then modify it to suit was thought to be a good plan. As the Humber was a 4 door saloon it is too long and it’s really the bulkhead and tail we require so the centre was cut out and added to the scrap pile. The bulkhead is too narrow for our chassis so we will have to cut it and set in a new panel but first we need to get the engine and box back in set the radiator in place and work backwards from that.

January 2024

Engine machining

Machining of engine components has been completed . Block was cleaned, skimmed and re bored with new pistons sourced. Crank had mains and big ends reground. Conrods where sent in as well to have new small end bushes fitted and reamed.

Thanks to Brian at B&E Randall for all the hard work www.banderandall.co.uk

As yet we have not seen the results apart from paying the bill, Alex will collect it from Randells when a dry clean corner has been created at the farm but at the moment it’s safe and dry where it is.

December 2023

Gearbox continued

December is more cleaning in the garage , bell housing cleaned and painted. Then on to the torque converter which we gave a spruce up with paint and fresh oil.

November 2023

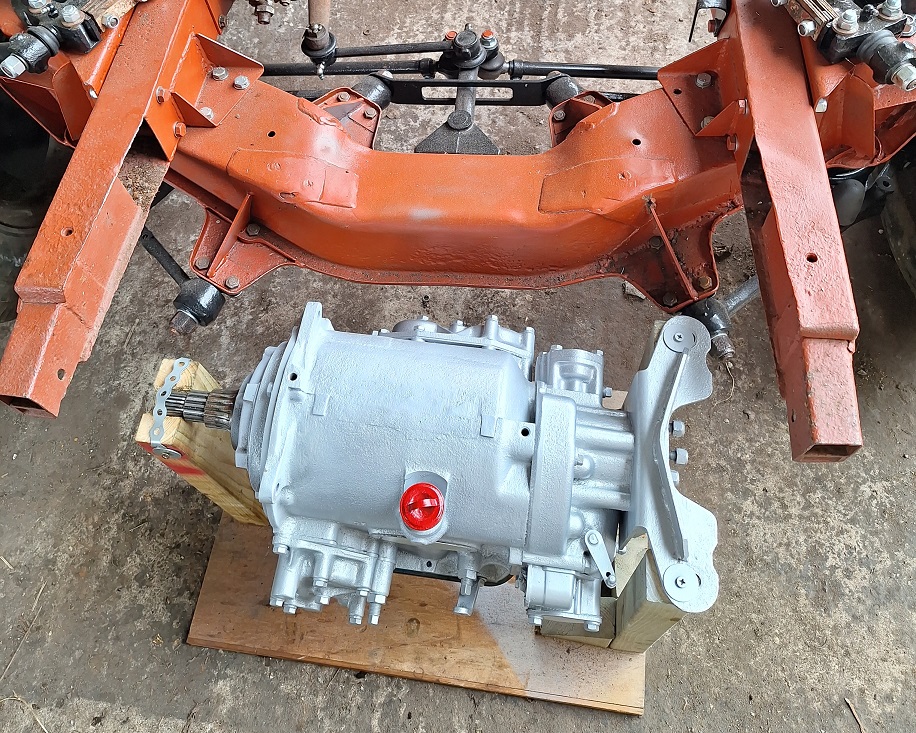

Gearbox

The Borg Warner DG-250 automatic gearbox is now back at our workshop. First job was a degrease then drain the oil out. The oil looks un-contaminated which after discussion with a local gearbox specialist we were informed is a good sign that the gearbox is best left alone as this type are very reliable and expensive once taken apart. So plan is just a clean and fresh oil. With that the sump was removed and along with the filter given a good clean. The front oil seal was also replaced as for £4 it would be stupid not to.

October 2023

Gearbox and Wheels

******Finally dropped engine block and crankshaft off to machine shop to be cleaned and checked.******

Installed the rest of the bolts into the front suspension and fitted front shocks. Removed rear brake drum to check shoes, feeling is with a clean it will stop again.

Removed the Borg Warner DG-250 automatic gearbox for checking and cleaning at our work shop over the winter.. Removing the gearbox reviled welds that needed cleaning up so this was also done.

A bit of experimenting with 20″ wheels was also undertaken to recreate the true 30’s look. First try were Ford, but offset was too much then hunting through another barn and a spare wheel for a Scammell fire pump was discovered which was a near perfect fit. So we know they’re out there just need to be found.

August 2023

Front Suspension

August and we finally could get back to the barn and continue the work. Front cross member welded and with that done we could re-build the suspension and get Sidd back on his wheels. This now allows us to move him around the yard and get closer to the welder.

Also picked up a nice brass fuel cap at a local auto jumble. Hopefully block and crank off to machine shop this month too.

Spring 2023

Slow work

Sidd has had to take a back seat for a while due to family matters but hopefully we can crack on again soon.

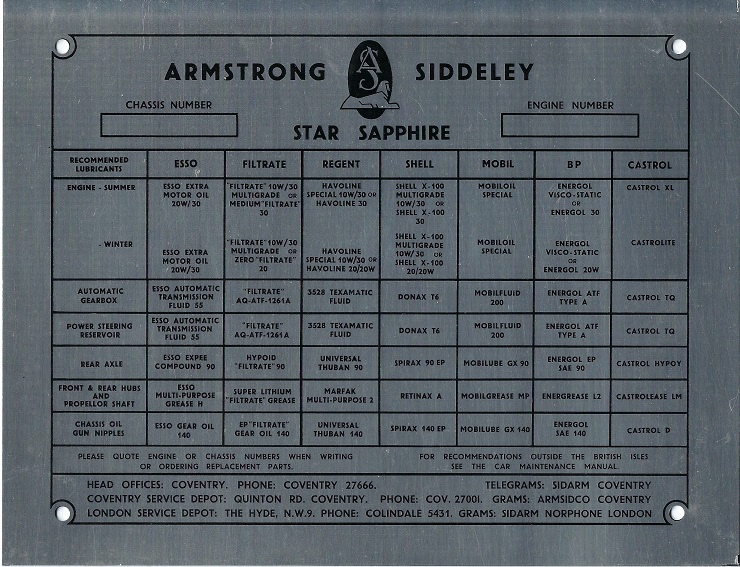

Picked up a reproduction lubrication plate from Ebay and new track rod end which are the same as used on series Land-Rovers.

Summer 2022

Barn Roof

Summer the main project was making Sidd’s house dry again ready for the winter.

April / May 2022

Still stripping down

Barn visit this month reviled what we already knew, the roof had not survived the winter storms. Hopefully this will be replaced over the summer , meanwhile spare parts have been moved to a dry area.

Removed prop shaft which looks to just need a clean and the brake servo which will probably be replaced.

Februry/March 2022

Front Cross member continued

Front cross member and other parts returned from blasters. Blasting has highlighted a few repairs to weld up very kindly taken on by Harry who’s skill level excides our own.

Wheel stations stripped, cleaned and re-greased fitted with new poly bushes and seals. Old discs have been refitted for time being and will be replaced before returning to the road.

Lower link arms cleaned, painted and fitted with new poly bushes. Top link arms just needed cleaning, painting and re-greasing.

January 2022

Front Cross member

Busy weekend in the barn at the beginning of the month both wheel stations, springs and shocks removed. With the wheel stations out of the way the front cross member and anti roll bar can also come off. Lots of cleaning and painting to do plus a bit of welding and at least 2 broken bolts to be replaced.

Second visit and more progress at the workshop this month. Engine mounts removed from front cross member , second calliper stripped, shocks repainted and fitted with new rubbers, rubber bump stops sourced, master cylinder stripped, top mount bolts replaced and cleaning painting of wheel station parts.

Cross member, springs and the badly corroded parts sent off for shot blasting.

Parts sourcing this month has identified the track rod ends as being the same as early Land Rover, one on order to check. Swivel bushes are being replaced with poly bush set from an MGB kit while using the original spacer. Ebay turned up a collection of spare the most helpful parts being a top end gasket set with the head gasket which has definitely saved a few pounds.

December 2021

Brakes continued

Brakes are still the main focus this month with the stripping and cleaning of the one calliper we have here at the moment. Investigation via the internet has revealed the same brakes callipers were fitted to Rover P4 & P5 which will make sourcing parts easier. New brake hoses have been bought and a hand brake from a 1936 17hp model has been found to fit hopefully on the outside of the cockpit. We’re still trying to source new discs as they are different from the ones fitted to Rovers . We may have to retain the original pads and disc for the time being for use when moving around the yard under its own power , maybe next year.

November 2021

Brakes

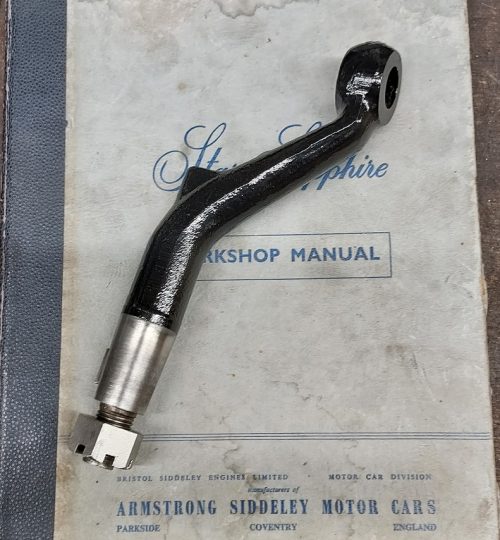

November dropping the engine block off to the machine shop is on hold for the moment so we have moved on to other jobs. After a short visit to the barn the near side front wheel station was disassembled to allow the disc and caliper to be removed. The discs and brake hoses will have to be replaced but the brake caliper hopefully can be reconditioned. Unfortunately while removing the steering arm to facilitate caliper removal the castle nut split so a new version was made in stainless steel.

September 2021

Instruments

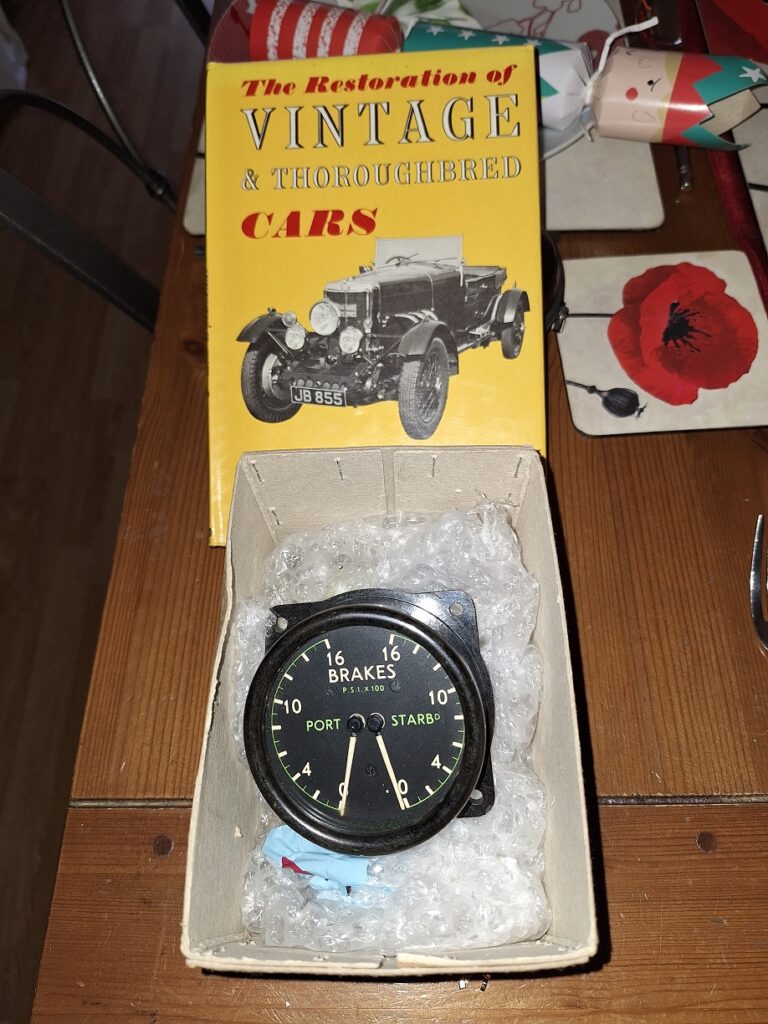

September and after a visit to the Beaulieu Autojumble we have started assembling the dashboards instruments and ordered a few parts from the owners club.

Also a few parts brought back form the barn for cleaning and painting.

August 2021

Engine Removal

August was just going to be a few little jobs with limited time in the barn, then we thought what the hell and proceeded to remove and strip the engine. Removal was a reasonably simple process particularly as there is no body work to damage . Stripping the engine was another matter, as the engine was seized the torque converter could not be removed till the engine could turn. Our previous efforts had resulting in 4 of the pistons moving with a gentle tap unfortunately the remaining 2 needed help from a block of wood and a very large hammer.

Next step is cleaning and inspection of the block, crank, camshaft, conrods etc. From first glance the camshaft looks ok, the crank will require a grind, small end bushes will be replaced and have already been ordered but the big question is the state of the cylinder bores which unfortunately doesn’t look good.

On the plus side the puncture was fixed in the now spare tyre by the replacement of the inner tube.

May 2021

Fire

May and a return trip to the barn and another attempt to free off the pistons in the block. The block was warmed through by burning petrol in each cylinder, the end result was that 4 pistons are letting the diesel pass by the rings which should aid removal hopefully in July.

All joints were lubricated and the near side front wheel swapped for the spare due to a puncture.

April 2021

Mascot

Quiet month on the car only real progress was the purchase of the mascot for the bonnet.

March 2021

Starter motor, dynamo, fuel pump etc.

Remaining ancillaries removed from engine for cleaning and overhaul, radiator found in another barn and parts stored with the car.

Fuel pump exchanged with new one. Starter motor found to be seized and brush springs broken, replaced springs un-seized and painted. Dynamo bearings very worn, replaced bearings cleaned and painted. H.T. leads replaced and new modern suppressed plug caps obtained.

February 2021

Cylinder head & Water pump

Cylinder head cleaned , skimmed and new valve seats cut. Valves and water pump parts supplied by Armstrong Siddeley owners club.

January 2021

Rocker cover

Rocker cover cleaned and painted, new nuts made to hold it down and distributor finished with new cap, points, rotor and condenser.

December 2020

Carburettors

Carburettors finished. Water pump stripped and found to require new seal and bearing assembly.

November 2020

Cylinder head strip

The car had obviously been left outside in the rain with air filters and rotor cap off allowing water into the carbs and then then the cylinders.

Cylinder head stripped and cleaned, valve seats and valves will have to be replaced. Distributor cleaned and unseized. Both carbs being cleaned and re-plated and painted

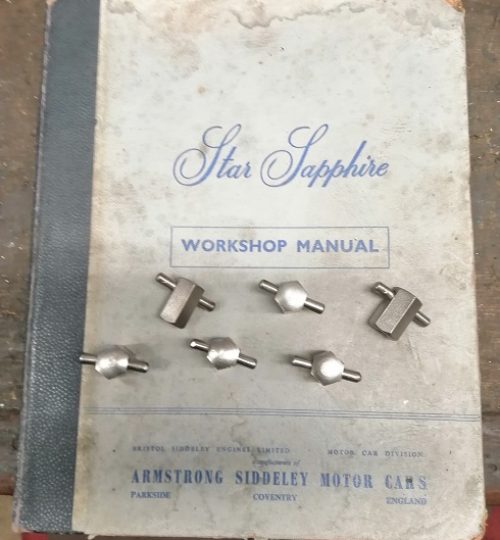

October 2020

Start of the job

Workshop manual and parts book found on eBay and so our journey with “Sidd” begins!

First job engine strip down and inspection. Pistons seized and old oil congealed every where else. Parts for refurbishment then taken back to our workshop for the winter.

A small Armstrong Siddeley oil pressure gauge turned up on eBay and we just had to have it , not sure if it’s from a car or one of the companies other products .

September 2020

As Found, The Start Of A Long Journey.

The car as found in a Alex’s barn needing a little TLC and a lot of body work. Due to the state of it and also it being an automatic it was left and ignored but as it has a log book and the engine, transmission, drive train, chassis, steering and brakes are all original Armstrong Siddeley finishing it needed to be done.

Alex purchased the car as part of a job lot of vehicles a few years beforehand and as we’re very old friend he has agreed that “Sidd” will have a home somewhere at his place for as long as needed.