Sidd’s diary charting the jobs and processes which will ultimately see him returning to the road.

December 2025

Lights and Brakes

So far this month it’s been mainly about working on the hand brake linkage but a trip to Kempton autojumble turned up a nice pair of Lucas side lights from the 1930’s.

November 2025

Engine and Rear Brakes

November and a nice long weekend up at the farm working on the engine and rear brakes.

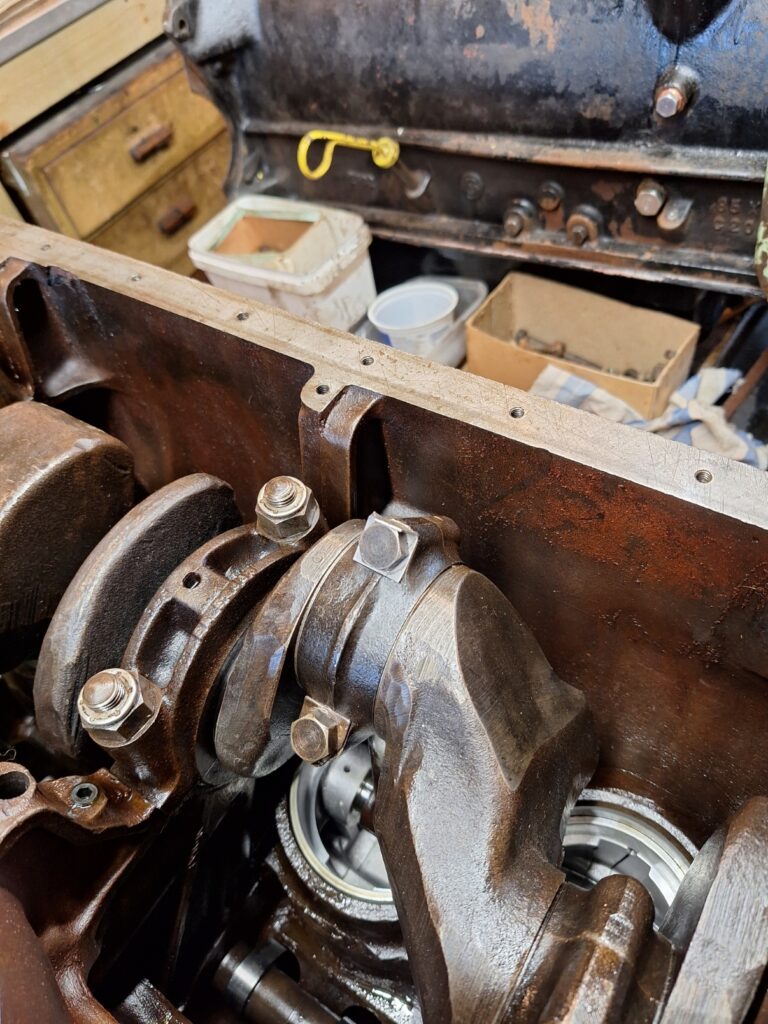

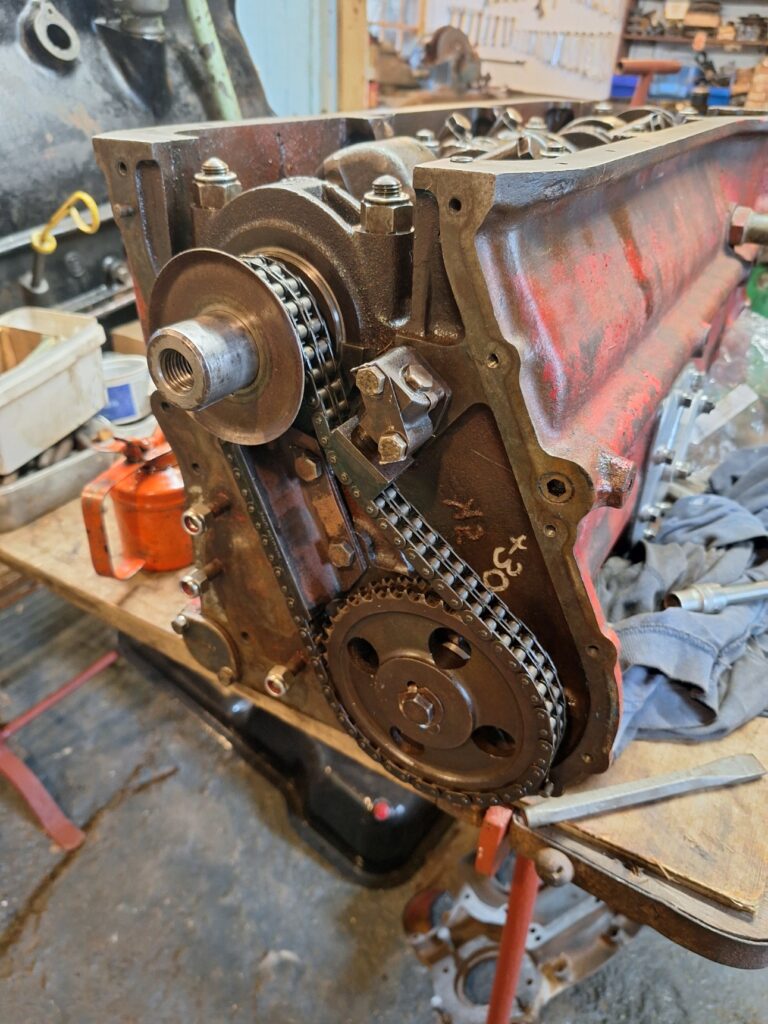

Weekend started well with after a bit of fettling by Brian the con rods are a perfect fit on the crank shaft and along with the pistons slid lovely into the block. All was going well till it came to peening over the tab washers and 2 of them broke off and dropped down into the block ! Was definitely time to walk away have a beer and come back next day. Friday morning started with making tab washer, after a bit of juggling with tin snips and drill new ones appeared. Cam chain was fitted and before the oil pump was inserted block was turned over and luckily both broken parts fell out. The oil pump, sump and drive plate now all fitted and that’s as far as far as we can go until we are ready to fit back into the chassis.

While we had time managed to strip the rear brakes down and apart from getting the brake cylinders overhauled everything else will go again with a clean. Alex is dropping the cylinders off to Past Parts for overhaul.

Summer 2025

Wheel PCD Adaptors Continued

Progress has been a bit slow over the summer as life and work has a habit of getting in the way. we did manage to complete another adaptor ( they take at least 2 hours of work ) and make a ratchet mechanism for the handbrake. A swivel ashtray was acquired for £1.68 so a place must be found for it and also another Lucas 9″ light to use as a centre spot light.

Brian has found 4 sets of big end shells so far, the search for 2 more continues.

May 2025

Wheel PCD Adaptors and Distributor

This month has been the continuation of making the wheel adaptors and also we have finally got around to completing the distributor conversion and we now have a means of driving a rev counter.

Alternative big end shells have been found, Lister-Petter single cylinder diesel engine are a match. Now we just need to track down 6 sets.

February 2025

Wheel PCD Adaptors

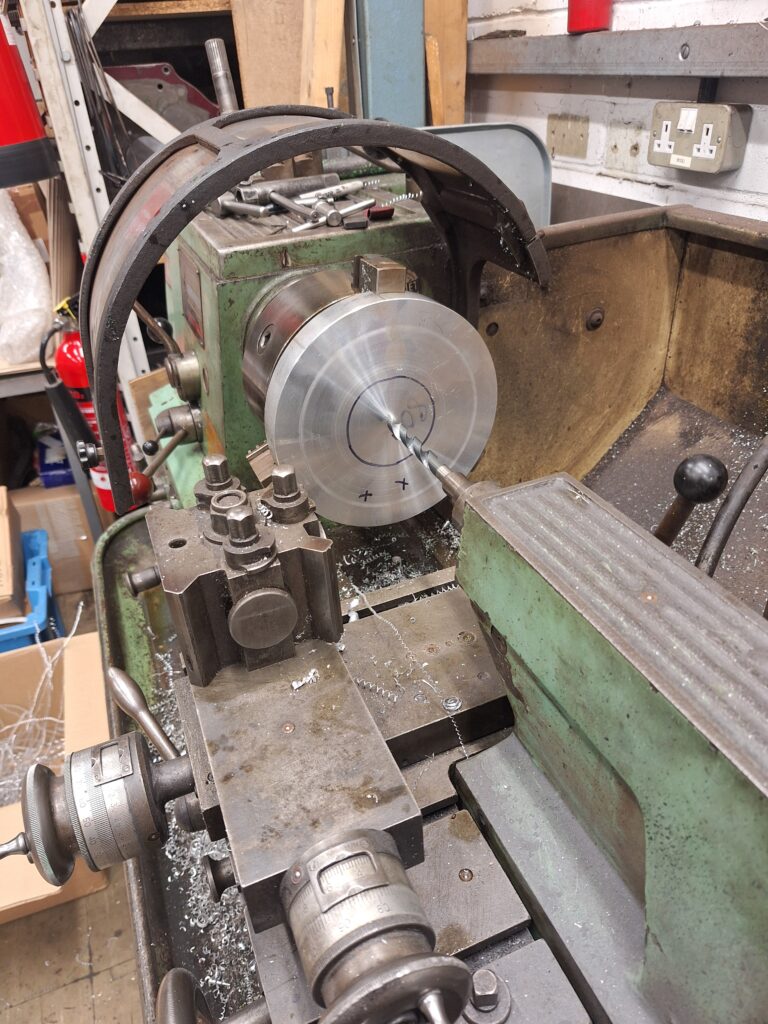

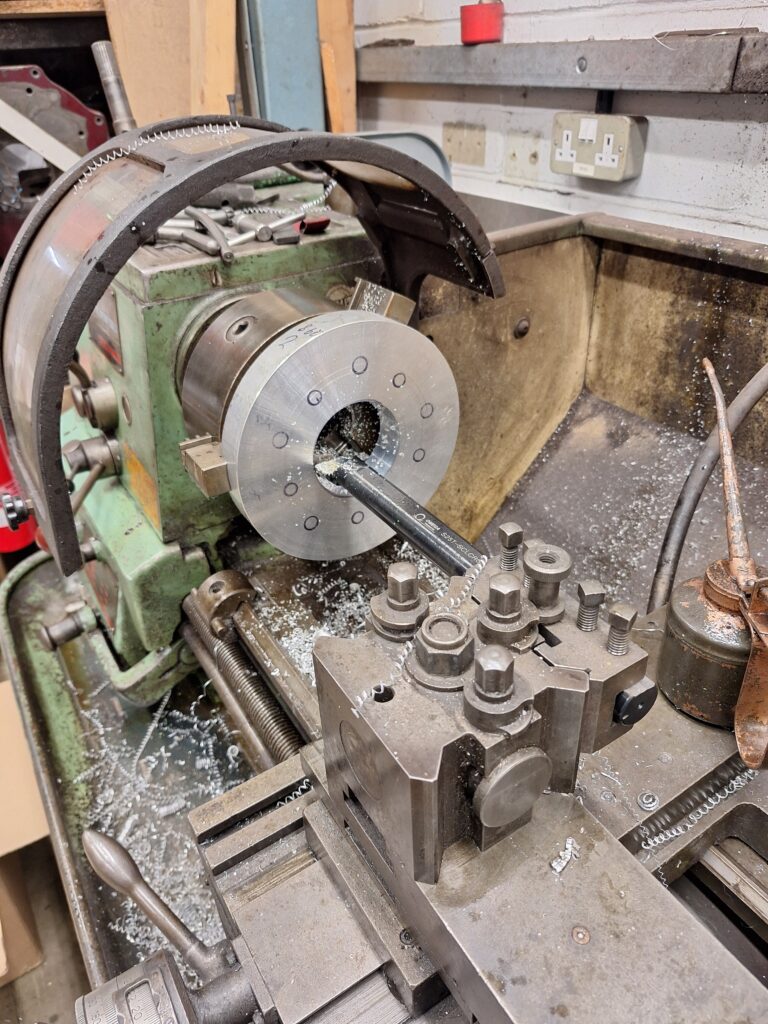

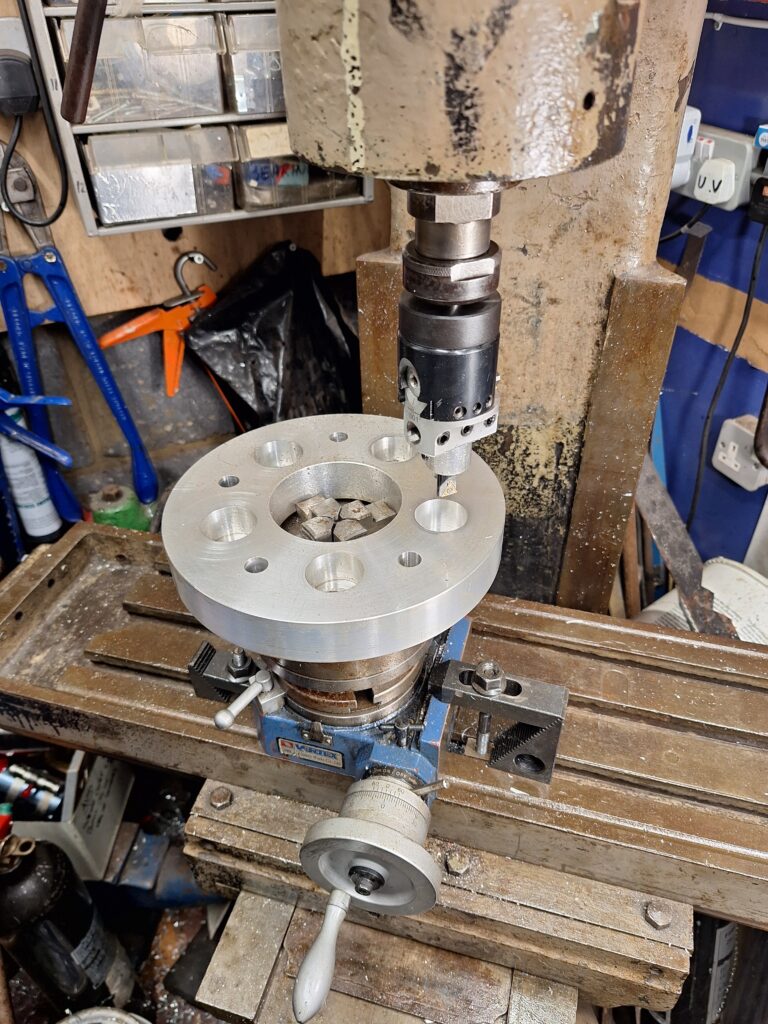

This month has been spent making adaptor plates to allow the fitment of the Ford wheels, Alloy blanks where ordered then trued up on the big lathe, the centre was bored to 82mm and then transferred to the mill.

5 recesses were bored to accept the Armstrong wheel nut then 5 more holes were bored and spaced between them at a larger diameter to accept 1/2″ unf wheel studs.

Also picked up another gasket set from Ebay, always good to have spares.

Unfortunately the supplier did not have the correct big end shells so the hunt is now on for another set, we have left this in Brian’s capable hands.

January 2025

Engine Reassembly

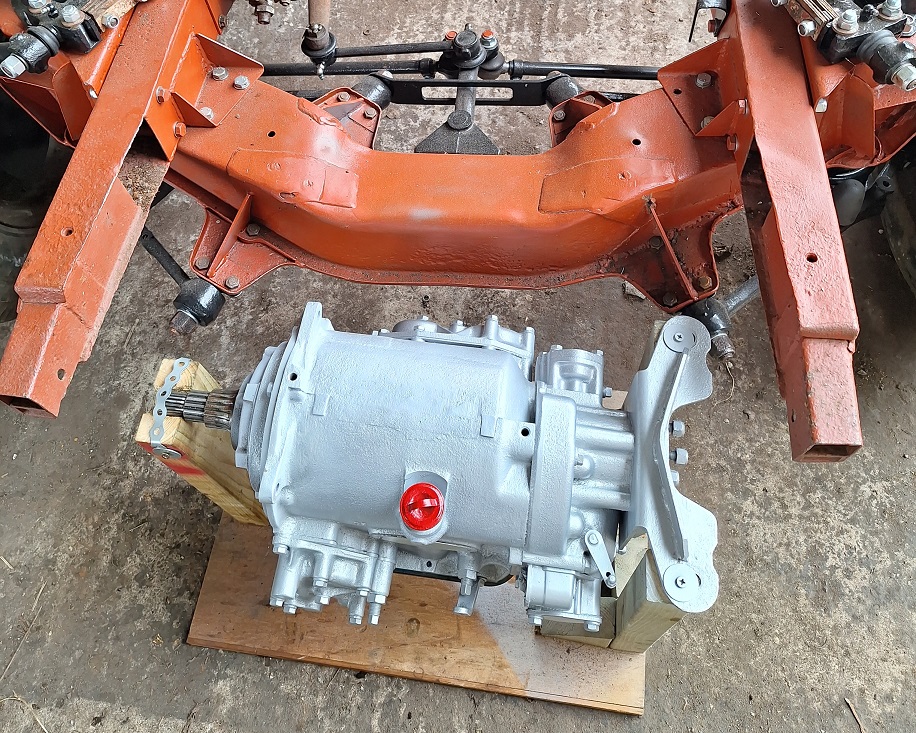

Engine re-build finally underway in 2025, crank and new main bearings fitted and torqued down. Camshaft installed and the timing gears and chain fitted and timed up. Pistons fitted to the con rods and all 6 sets of rings gaped. Unfortunately when we went to fit the new big end shells the box had been miss labelled and completely wrong shells had been supplied. Hopefully this is a simple mix up by the suppliers and fingers crossed is easily resolved. Moving away from the engine shop we moved into the barn for a few hours to install the servo on its new bracket made last month and more brake lines were made.

Also tackled on this visit to the barn was the subject of wheels, while scratching around doing something unrelated early Ford wheels came to mind. Model A wheels are the right diameter 21″ and 5 stud but with a different stud diameter to Armstrong Siddeley , the thought is with an adaptor plate they could be made to fit. The hunt is on for Model A wheels and with luck we may have some before the month is finished.

We had a stroke of luck and found a set of 5 wheels and tyres on marketplace, day out to Sussex to collect them. Next job is to make a set of adaptor plates.

December 2024

Engine has returned

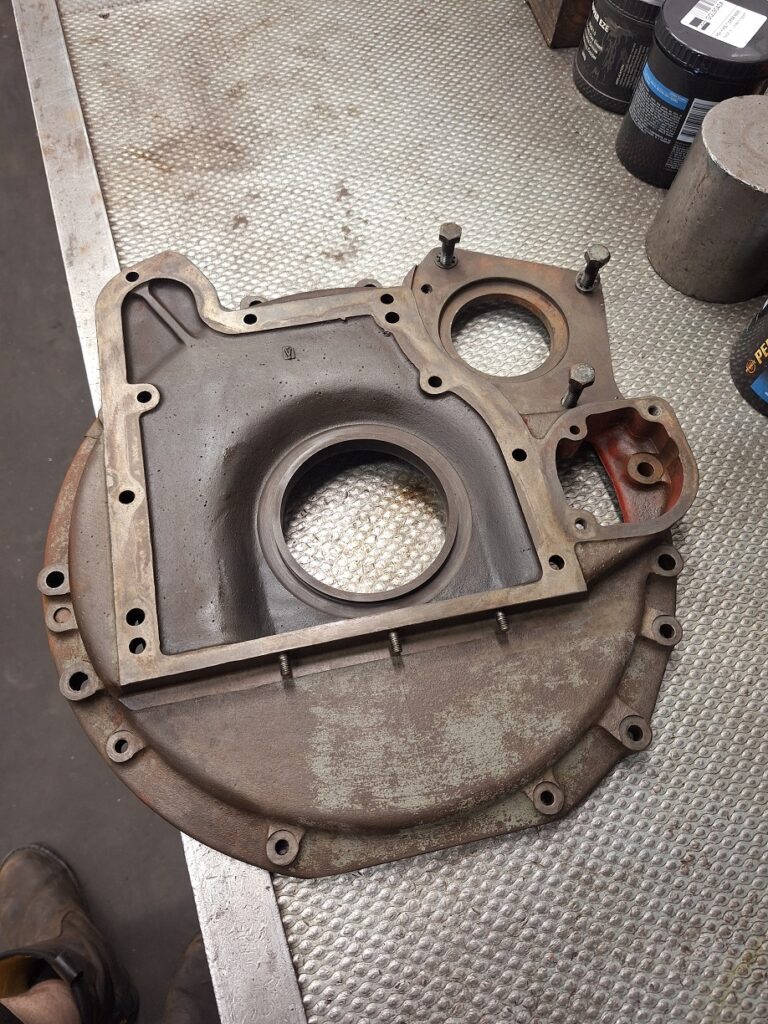

December and the engine was finally collected from the machine shop. 0.30″ oversized pistons, 0.20″ grind on main bearings, 0.10″ grind on big ends, the components have been put in the engine shop and hopefully will start being re-built in January.

Another addition to Bay 7 is a bench from the workshop of the Royal Engineers Museum Chatham and a vice found in the back of Alex’s welding shop. First job was the fabrication of a bracket for the new after market brake servo. The diff cover was re-fitted with new gasket, level plug and oil.

November 2024

Barn visit and surprises

Barn visit November started with a very nice surprise from Alex, a pair of 8″ Lucas head lights and matching side lights followed by a large handbrake arm ( probably off a truck but it’s in keeping with our style ) donated to Sidd. Rear leaf springs and associated bushes and linkages re-fitted. Hand brake pivot and a few other brackets re-fitted as well. Tried to remove level plug on the diff to re-fill with oil only option after various spanners and blow torch failed was to remove cover plate to the workshop where the level plug lost the fight. As the differential is a Salisbury type a new gasket and plug are quite common as they are used on many vehicles from Land Rovers to E-Types so are easy to source.

August / September 2024

More cleaning and painting

While we are away from the barn there are a few small jobs we can get on with. Cleaning and painting all the rear leaf springs and all their associated brackets, bolts etc. Fan belts have been purchased, they are the same as used on Land Rover Series 2A. Plasma cutter has been employed to make support brackets for the front engine mount bracket, these have been made longer and will be cut and welded when the engine is reunited with the chassis. Poly bushes have been sourced for the leaf spring shackles, they are a Ford kit which are a little long so 5mm was removed with the help of the mill.

July 2024

New Home and Chassis Welding

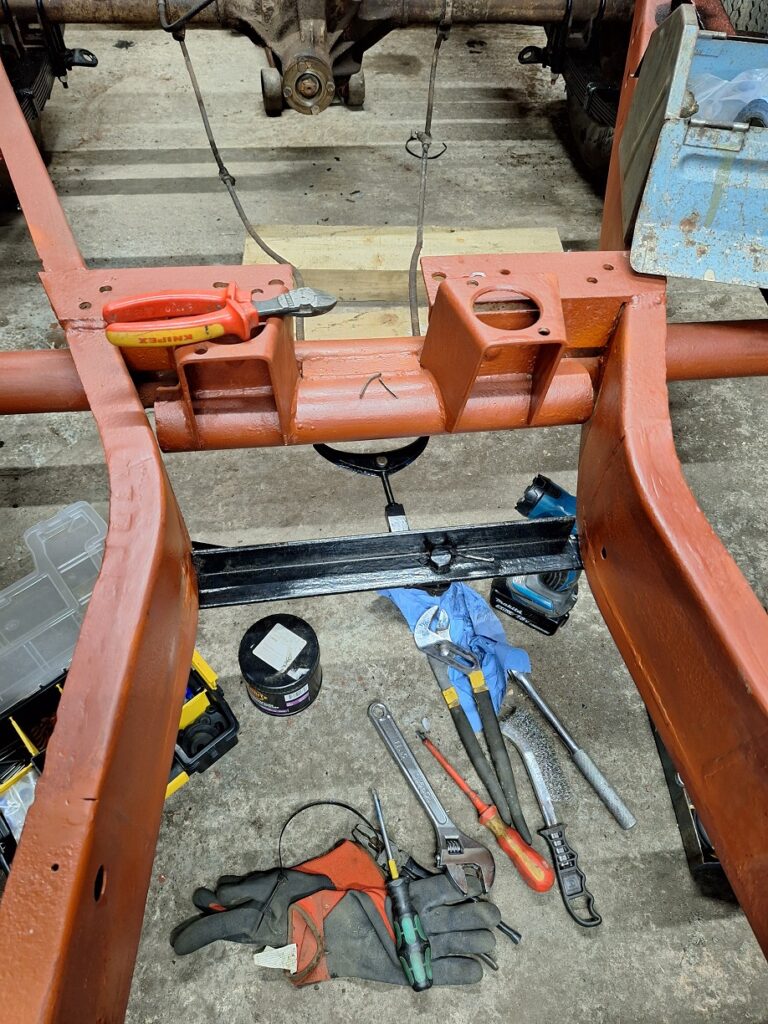

July saw Sidd moving into his new home in bay 7 in the M.T. shed. Lights and power have been installed and he has a dry corner to call his own and allow the journey to continue. The hole that was found under the chassis has been welded and a few other welds tidied up and with the chassis exposed cleaning underneath and red oxide could be done. Final job of the weekend was to drop the rear axle and remove the rear springs for cleaning and inspection back at home.

June 2024

More Jobs

Purchased another distributor from a TR6 which has a tacho drive so hopefully will be able to drive the rev counter purchased last month by installing my original distributor internals into it.

May 2024

Jobs

The weather has finally cleared enough to allow more works to continue on the barn roof.

Bit of time spent on Sidd this month, chassis cleaning, removing of engine mounts, stripping of bulkhead and a bit of playing mocking up the look.

We were donated a front grill off a 1930’s Sunbeam Talbot 4/3Litre and an aero screen ( another will be purchased to match)

Also a friend was moving and a nice 1.75 ton trolley jack was donated to Sidd, thanks Paul.

Just won on Ebay a dash board, mainly want it for the speedo and rev counter.

March 2024

Bodywork

As Sidd has no bodywork you have to start somewhere, the body on a late 20’s early 30’s Humber 16/50 tourer which was bought to be used as a donner vehicle was available. It has some usable panels and it’s easier to actually start with something and then modify it to suit was thought to be a good plan. As the Humber was a 4 door saloon it is too long and it’s really the bulkhead and tail we require so the centre was cut out and added to the scrap pile. The bulkhead is too narrow for our chassis so we will have to cut it and set in a new panel but first we need to get the engine and box back in set the radiator in place and work backwards from that.

January 2024

Engine machining

Machining of engine components has been completed . Block was cleaned, skimmed and re bored with new pistons sourced. Crank had mains and big ends reground. Conrods where sent in as well to have new small end bushes fitted and reamed.

Thanks to Brian at B&E Randall for all the hard work www.banderandall.co.uk

As yet we have not seen the results apart from paying the bill, Alex will collect it from Randells when a dry clean corner has been created at the farm but at the moment it’s safe and dry where it is.

Diaries for the previous years

Diary pages form the early years of project Sidd